8 Things You Need to Know to Effectively Sell Roll Banners

This article assumes that the reader has had SOME experience in the printing and/or ad specialty industry. It is written with the intention of providing information, tips and hints to increase your chances of successfully engaging clients that are interested in purchasing roll banners.

As a point of clarification, Roll Banners are defined as:

- Printed poly roll stock or vinyl rolls, containing identifiable company, product or event logos and marketing messages, rewound into easily usable rolls

- Cost-effective promotional products widely used to advertise concerts, political rallies, radio station, sporting, and other events

Some synonyms for Roll Banners include:

Plastic roll banners, roll-a-banners, roller banners, roll banners, event banners, plastic banners, radio station banners, racing banners, banner rolls, perforated banners, rolling banners, polyethylene banners, plastic banner rolls, disposable banners, recyclable banners, political banners, biodegradable banners

1. Has your customer already printed roll banners using their current art?

If the answer to this question is “yes”, then the odds are that you will not sell the deal. The reason for this cold-hard fact is that your customer has already spent HUNDREDS of dollars on printing plates.

On average, 24″ plates cost between $300 and $400 PER color. For 3 color banners, your customer will have already invested between $900 and $1,200 in printing plates. They are going to want you to eat that expense in order to gain their business.

Usually, eating the cost of the expense that your client has already incurred for printing plates does not make business sense. It may in rare cases. Usually it doesn’t. You will save a lot of time and effort if you know, going into a deal, that the client has already purchased plates for the banners in question, and has no intention of buying them again.

2. Roll Banners … Does your client need at least 2,000 linear ft?

We like to say that buying Plastic Roll Banners “is like getting a GREAT DEAL on 5 gallons of peanut butter. If you run an aircraft carrier, this is absolutely a great buy. If you just need peanut butter for your family, this is a bulk purchase that doesn’t make business sense.” The cost per banner may be only $1.50, but you need to buy 2,000 linear ft of them. Like buying bulk peanut butter, it doesn’t make economical sense unless your clients’ needs justify the size of the purchase.

Why did we arrive at 2,000 ft as our minimum run? We need to cost justify our “hands on” set up time. Our average set-up time to mount plates, put in PMS matched inks, un-mount plates and clean up press, hoses and ink stations is 30 minutes per spot color. Because the press runs at 450 – 500′ per minute, the minimum print run is 2,000 linear ft or 6 – 8 minutes of press time.

It is common for us to have resellers request pricing for “1 or 2 rolls” of banners when they engage us about roll banners for their clients. In these cases, it is common for us to refer the reseller to vinyl roll banners. They are the perfect complement to plastic roll banners. Many times you can meet your clients’ banner needs with vinyl roll banners for less money than the cost of printing plates needed to print plastic roll banners.

3. How many roll banners will my client get from their print run?

To compute the number of banners a print run will yield, just divide the length of the run by the individual banners “repeat” length.

Determining banner yield per 1,000 linear feet:

- Roll banners with a 24″ repeat will yield 500 banners per 1,000 linear feet (1,000 ft / 2 ft = 500 banners)

- A 30″ repeat will yield 400 banners per 1,000 linear feet (1,000 ft / 2.5 ft = 400 banners)

- A 36″ repeat will yield 333 banners per 1,000 linear feet (1,000 ft / 3 ft = 333 banners)

- A 54″ repeat will yield 222 banners per 1,000 linear feet (1,000 ft / 4.5 ft = 222 banners)

4. How many banners will my client get per roll?

The answer to this question is a function of the banner “rewind” length. In flexographic printing, it is common practice to print “roll to roll” using 200 lb rolls of poly. We will print the entire run, or even several runs using the same roll of poly. After the roll of poly has been printed, we then “rewind” it into smaller rolls that are easy to carry. Our standard rewind is 500 linear feet. We standardized on 500′ rolls because they provide the best trade of between weight and ease of use. Additional rewinds are available at a modest additional fee.

- 18″ rolls weigh (approximately) 16 lbs

- 24″ rolls 22 lbs

- 30″ rolls 28 lbs

- 36″ rolls 34 lbs

We rewind 48″ banners on 250′ rolls. In our opinion they are too heavy to wind onto 500′ rolls.

To compute the number of banners found on each roll, just divide the length of the roll (in our case, 500′) by the individual banners’ “repeat” length.

Determining banner yield per 500′ roll:

- Banners with a 24″ repeat will yield 250 banners per 500′ roll (500 ft / 2 ft = 250 banners)

- A 30″ repeat will yield 200 banners per 500′ roll (500 ft / 2.5 ft = 200 banners)

- A 36″ repeat will yield 167 banners per 500′ roll (500 ft / 3 ft = 167 banners)

- A 54″ repeat will yield 111 banners per 500′ roll (500 ft / 4.5 ft = 111 banners)

5. Does your client REALLY need 4 color process (4cp) banners?

** PLEASE NOTE THAT THE MAX REPEAT FOR 4 COLOR PROCESS FLEXO PRINTED ROLL BANNERS IS 36″ **

** PLEASE CALL NORTHCOAST BANNERS AT 800-231-4213 IF YOU HAVE ANY QUESTIONS ABOUT 4 COLOR PROCESS ART LAYOUT **

Every day we are given specs for plastic roll banners that specify four color process (4 cp) banners. Occasionally, the roll banners DO require 4cp. Usually they don’t.

We print plastic roll banners using flexography. In this environment, unlike digital printing, it makes all the difference in the world whether your client actually requires 4cp.

With digital printing, the above two banners (meaning the spot color art on the left and the process color job on the right) are printed using the exact same process.

The art files are RIPPED and then sent to the printer, where the printer microprocessor interprets the dot pattern and ink lay down. Then the microprocessor signals, via the slider board, the nozzles to spray cyan, magenta, yellow and black in accordance with the correct color profile.

Flexography is different. It is a lot more “hands on” than digital printing. In flexography, the art is RIPPED, with the rip software specifying CMYK, based on the colors included in the art. Once the art is ripped, very expensive printing plates are made in accordance with the color separations specified by the software. After the plates are made, they must be must be mounted on cylinders and loaded into the press where all the colors must be registered properly. It is only after the colors are registered properly and the banners are “in color” that the press throughput can be increased to production speed.

Because of the significant “up front costs”, 4cp plastic roll banners require a much longer minimum run than spot colors to cost justify the run. Whereas in years past, our minimum run for 4cp banners was 25,000 linear feet. Now, because of some technological breakthroughs, we can now print runs of 4cp plastic roll banners as short as 10,000 linear feet.

6. Four color process banners – how do you tell if your client REALLY needs them?

We like to say that printing with spot colors is akin to “coloring in a coloring book” with REALLY powerful crayons and 4cp printing is akin to creating photographs.

The following list gives some general guidelines to help you determine if your client REALLY needs 4cp banners.

- The art contains more than 6 spot colors and the spot colors (beyond 6) must match PMS values.

- There are photographic images in the art

- There is a need for accurate skin tones

- You just can’t get the subtle effects you need using spot colors

- They are willing to pay a substantial premium (as much as 300%) for the first 10,000 linear feet of their banners

We are able to print up to 6 spot colors, and it is common for us to be able to print banners using spot colors that at first blush appear to be 4cp. In cases where the client is specifying 4cp, feel free to send us your art and we will “break it down” for you to determine if it REALLY requires 4cp.

7. Roll banner orders – how long DOES it take turn them around?

It takes us 2-3 weeks for us to turn around spot color print runs. 4CP banners require 4-6 weeks.

The increased complexity of making 4cp plates and the increased length of the minimum run, makes the startup investment for 4cp plastic roll banners substantially greater than the start up investment needed for spot color banners.

In addition to the increased investment needed for 4cp plastic roll banners, they also require more time to produce. Our average time to produce spot color banners is 2-3 weeks. 4cp roll banners require 4-6 weeks to produce.

For more information on roll banners, please contact us by e-mail at info@northcoastbanners.com or call us at 800-231-4213. We will be happy to answer your questions!

8. Full Bleed Roll Banners – does your client require them?

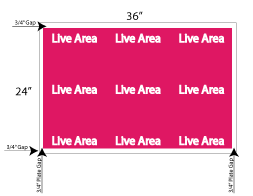

- When creating roll banner art for your clients, it is best to restrict your design elements to the “live area” of the banner.

- The live area is defined (roughly) as the print area inside the “margins” of the roll banner.

- The margins constitute the gap that remains between the edge of the printing plate and the edge of the poly (at the web) or the plate gap (at the repeat).

- We prefer 1/2″ to 3/4″ gap on all sides of your roll banner design. See the roll banner “live area” illustration below.

When roll banner design elements impinge on the gap outside the live area, we will work with the designer to eliminate the design flaw. However, on occasion, the roll banner specs will absolutely require a design that has no gap between instances of the banners, and no white edge at the top and bottom of the banner. These are cases we refer to as “full bleeds”.

How Northcoast Banners Prints Roll Banners With “Full Bleeds”

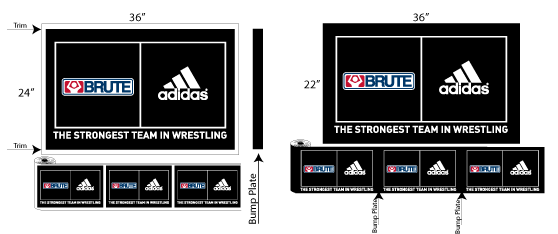

We print roll banners with full bleeds on a case-by-case basis. Please submit artwork for evaluation. Trimming the outer edges of the roll banners is simple. All we need is at least 1″ of margin to ensure a safe and accurate trim. The challenge is in elegantly eliminating the plate gap.

Flexo presses do not allow continuous print. Because of the way plates mount on the cylinder, a gap occurs between the lead and trail edges as they butt together. This area is referred to as the “plate gap”. The key to creating the seamless effect between roll banner instances is to integrate the plate gap into your graphic design. Compensate for the plate gap fill into the roll banner graphic design by using a solid color BUMP plate that is wider than the normal gap fill. The BUMP plate can butt up to the primary design elements eliminating the appearance of any plate gap fill. The key is in making the seam as close to invisible as possible.

If you design your roll banner art with colors other than white between the images, select a PMS color that blends well into the background. By using our 5th or 6th printing deck, a spot color can be printed to fill the plate gap.

Our experience has shown us that black is the absolute safest color to use to fill the plate gap in your roll banner design. We have successfully created full bleed roll banners with bump plates other than black, HOWEVER, black is by the safest choice of colors for your bump plate.